UCM

medium voltage underground cable monitoring

The needs

The medium voltage electrical grids (from 1kV to 35kV) are used to transport energy between the high voltage and the low voltage substations, located throughout the national territory in residential and industrial areas or directly within small and medium-sized industrial sites.

The medium voltage electrical grid can be overhead (supported by towers and poles) or underground, based on the characteristics and the requirements of the places to be served or crossed. In large urban site this electrical grid is placed, for obvious reasons, under the ground surface at a depth of 0.9m to 1.2m.

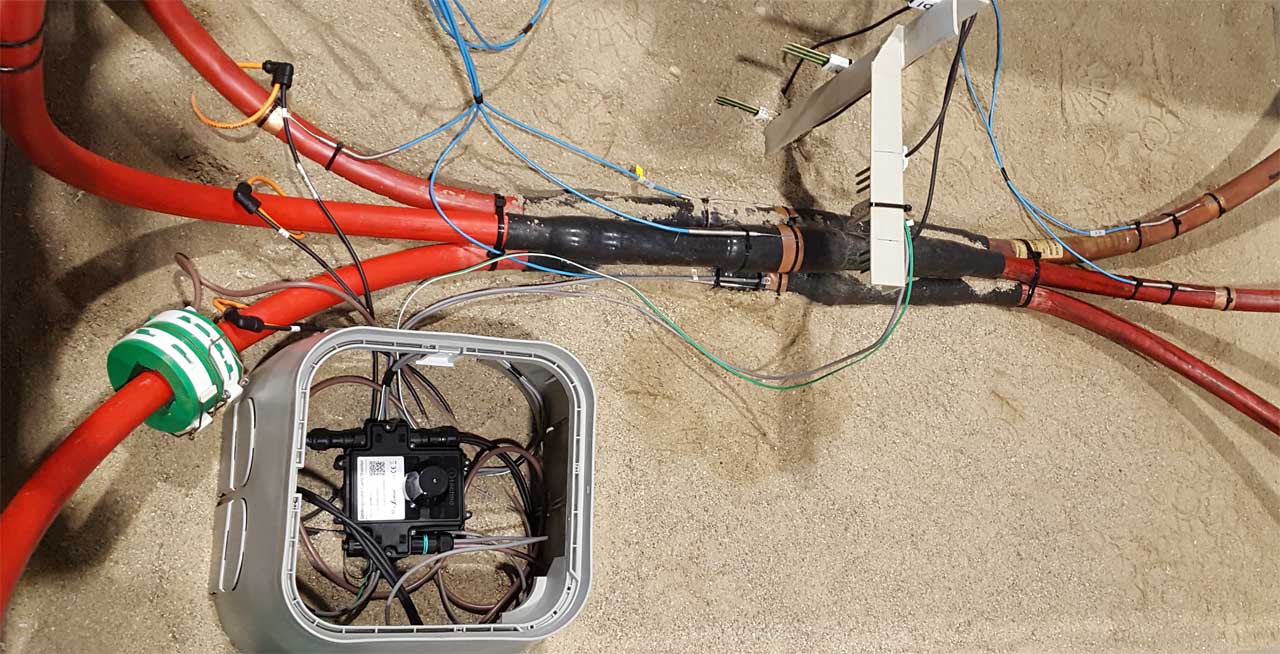

The three-phase medium voltage cables, and the junction devices between the various grid segments,

are commonly laid underground with different techniques aimed at minimizing possible mechanical stress and maximizing the effect of thermal dissipation produced by the surrounding ground.

Ground conditions and its adherence to the cable and the joints are therefore a crucial factor for the correct dissipation of the produced heat.

Recent studies on the dependence on the environmental and cable load conditions show a strong correlation between their failure rate and bad climatic and load situations.

“During summer, extreme conditions associated with high periods of heat can occur, which include considerable thermal stress on the components of the underground distribution grid, increasing the probability of failure. The phenomenon affects several Italian cities every year during summer, where the high increase in cooling demand implies considerable stress on the joints of the underground cables. An example is the city of Milan, for which the data provided by the distribution company Unareti show a high failure rate between the months of June and August.

- Climate changes lead to an increase of high periods of heat, both in intensity and duration

- Soil temperature increases a lot in urban centers due to the presence of an extremely impermeable and bituminous surface (strong heating and drying of the soil layers below the urban surface).

- All this determines a worsening of the heat exchange between the cables and the ground, and therefore an increase in the probability of critical conditions, especially for the joints. Increase thermal resistivity of the soil.

- Cable overheating also causes premature aging of the insulation with a consequent increase in the probability of failure

- Very serious situation due to the increase of demand for cooling energy” (source RSE SpA)

The damage to an underground medium voltage cable (loss of insulation or bursting of a joint) causes problems and great difficulty in restoring, having first to search and identify the underground breaking point and then proceed with excavation works to replace the damaged parts. The inconvenience of these operations is further amplified when the breakdown occurs in highly populated urban areas or in historic city centers.

Research and experimentation are in progress aimed at better modelling the behaviour of the various types of underground cables and joints in relation to the conditions of the ground, and the possible techniques for laying and covering them. Other behavioural models are derived from the analysis of statistical meteorological and grid failures data.

The institution which is carrying out this analysis and modelling expressed the need for an active monitoring system that continuously monitors the significant statistics related to this phenomenon. This device can also become an effective in-field monitoring system that allow to know the real-time working conditions of underground cables and to optimally manage the resources of the medium voltage distribution grid, maximizing their energy rate and minimizing the risks of failure due to overheating of its components.

These needs led iSEMAR to define an IoT device expressly designed for this type of application.

The challenges

- Detection of the working temperature of the medium voltage underground cable or joint

- Detection of the temperature and humidity of the soil (tensiometric level) near the underground cable

- Measurement of the flowing current on the three-phase cable using an openable Rogowski

- Bidirectional radio communication in LPWAN technology (NB-IoT and LoRaWAN)

- Powered by a rechargeable battery with a high operating autonomy (ultra low-power design)

- Battery charge using magnetic energy harvesting (openable CT) on the monitored cable

- IP grade and chemical protection for underground use

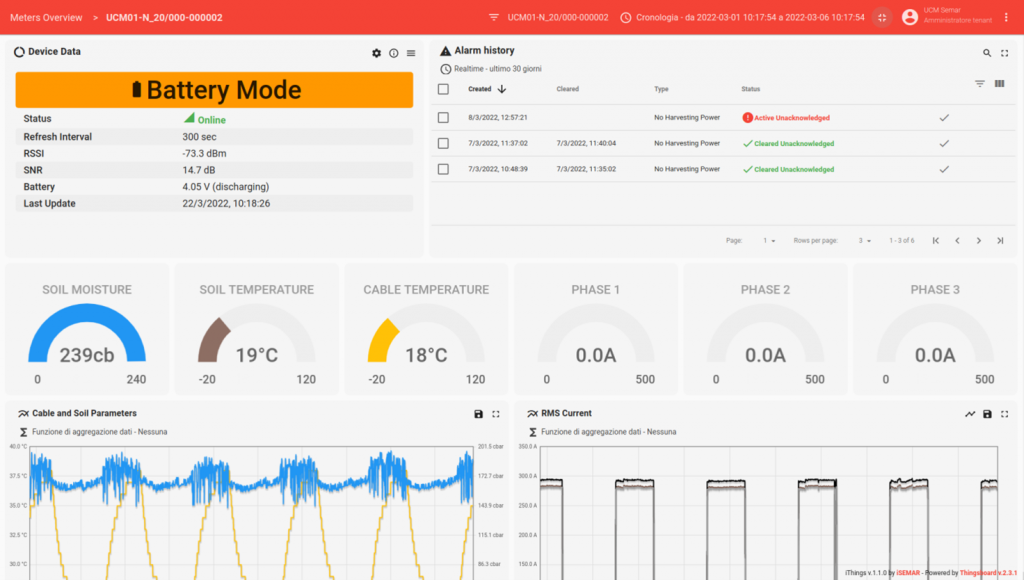

- IoT platform for data acquisition, processing and storage, and for alarms and notifications generations

- Dedicated WEB portal for viewing, exporting and analyzing historical data

The realization

The UCM01 is an IoT device for active monitoring the main operating parameters of power grid underground cables and joints, designed to help in the prevention of possible failures and disservices caused by an excessive energy flow compared to the real working conditions of the monitored parts.

The device periodically measures the temperature of the underground cable or joint, and the temperature and humidity level (tensiometric level) of the surrounding soil. The RMS value of current flowing on the three phases are continuously monitored over configurable intervals, producing both aggregated RMS values and minimum/maximum RMS.

The UCM01 is autonomously powered using an openable current transformer, applied on one on the monitored cable phase as a magnetic energy harvesting source. In this way the integrated battery is also recharged, and thanks to an ultra low-power design, is able to guarantee up to 90 days of continuous operation even in absence of flowing current.

All collected data are periodically transmitted to a specific iTHINGS application using an integrated LPWAN connectivity, NB-IoT (UCM01-N) or LoRaWAN (UCM01-L), and their relative integrations with the corresponding network platforms. The WEB iTHINGS application, available as IaaS, PaaS and SaaS, stores and shows all data received from the devices, allowing various views and aggregations as well as exporting them to other applications. The same iTHINGS application also allows the device remote management and configuration, in order to best adapt it to the real needs of the monitored area.

The device has an IP68 protection degree which allows the use in and underground environment without the need for additional protection elements.

CONTACTS

Via Sardegna 5, 60022

Castelfidardo (AN)

Italy

T +39 071782481

F +39 0717824824

info@isemar.biz