PMS

Industrial process monitoring system

The needs

A European business unit of a large multinational group, operating mainly in electrical components area, expressed the need to monitor the usage of its own equipment for plastic moulding and metal bending/blanking used by various suppliers on the European territory.

The request for a remote monitoring and tracking of their own moulding/bending/blanking equipment was aimed to obtain a precise and autonomous control of their working parameters and cycles, especially for the periodic or extraordinary maintenance operations performed by the supplier which cause production stops.

The real-time monitoring of equipment working parameters, along with the possibility to analyze the historical data acquired from the various suppliers, allows the optimization of production processes and the scheduling of preventive maintenance operations. These advantages lead to benefits on production costs and on the quality of the products realized with the monitored equipment.

The required monitoring system also had to be easy to install (completely plug&play) and autonomous enough not to require any kind of technical support from the supplier to whom the monitored equipment was delivered.

The challenges

- Detection of metal parts movements cycles (opening, closing, rotation...) with speed of up to five cycles per second

- Detection of equipment activity even when the monitoring device is not connected

- Detection of temperature and removal of the monitoring device

- Wireless and autonomous WAN connection for unlimited data tracking on a dedicated cloud service

- Large local storage (up to 50000) for events and activity parameters in absence of a netwotk connection

- Dedicated WEB application for data view and historical KPIs analysis

- Flexible definition of periodic maintenance operations and tracking performed activities

- Configuration of alarms and notifications on multiple events and conditions of monitoring equipment

The realization

The Process Monitoring System (PMS) is a completely plug&play, flexible and secure IoT industrial system, created for the real-time monitoring of equipment used in industrial manufacturing processes.

The PMS system is composed of several devices which, thanks to the modularity of their firmware and management software, allow the customization of the entire system according to the specific customer needs and the monitoring of equipment activities and manufacturing processes.

The realized system perfectly fits the needs required by our customer. It is composed of various devices:

- Sensor Units applied to the equipment to detect the relevant parameters

- Processing Units for a local pre-processing of raw data detected by the Sensor Units

- Gateway Units for a wireless and secure connection of the Processing Units to the dedicated cloud application

All devices are automatically recognized and configured for the requested application by a centralized self-configuration remote service.

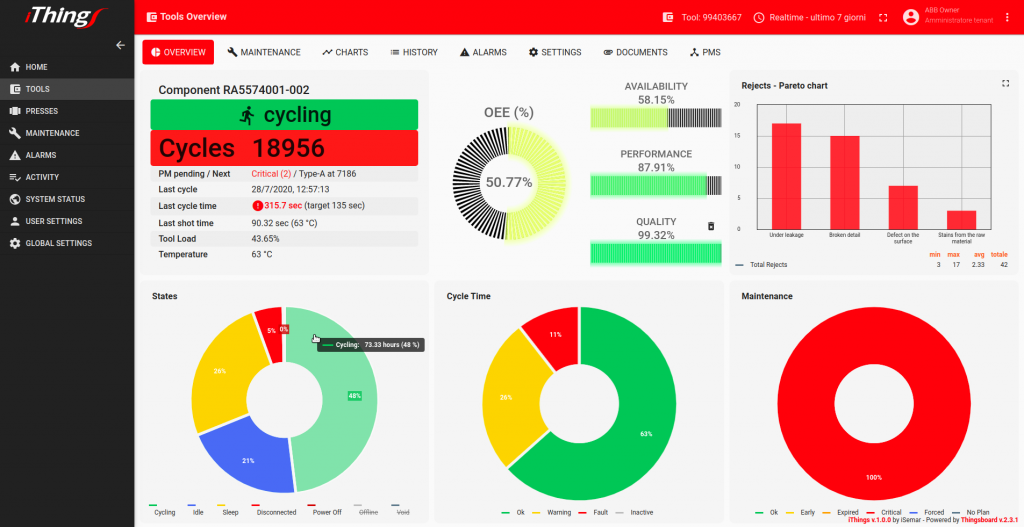

A dedicated WEB application, available as IaaS, PaaS and SaaS, allows the complete system management and the historical data analysis, in order to obtain multiple KPIs (OEE, availability, performance, quality...) about the production process using the monitored equipment.

The same application, which supports differentiated and customizable access level for admin or supplier users, also manages the scheduling of maintenance activities on monitored equipment and tracks their execution, in addition to any extraordinary activity on the equipment itself.

CONTACTS

Via Sardegna 5, 60022

Castelfidardo (AN)

Italy

T +39 071782481

F +39 0717824824

info@isemar.biz